Polyester fiber mai ɗaukar sauti mai ɗaukar sautiwani nau'i ne na fiber na mutum, wanda aka yi da giciye mai girma uku tsakanin zaruruwa da zaruruwa, haɗin gwiwa tare da juna, yana nuna ɗan ƙaramin gibi, don samun sakamako mai kyau na ɗaukar sauti. Ƙwararren mai ɗaukar sauti yana da halayen haɓakar sauti, kariya ta muhalli, haɓakar harshen wuta, zafi mai zafi, adana zafi, juriya na danshi, juriya na mildew, da dai sauransu. Kuma ya dace don kawar da ƙura da yankewa, kwanciyar hankali mai karfi da babban farashi. Ya dace da wuraren wasan kwaikwayo kamar manyan gidajen wasan kwaikwayo, dakunan kide-kide, gidajen sinima, wuraren yin rikodi, dakunan taro, dakunan taro, dakunan KTV, gidajen sinima, masana'antu, dakunan bebe, dakunan karatu, dakunan tambayoyi, da sauransu.

Za a iya yanke bangarori masu ɗaukar sauti na fiber polyester zuwa nau'i daban-daban bisa ga bukatun abokan ciniki daban-daban a lokuta daban-daban. Saboda haka, yankan da naushi sune hanyoyin sarrafawa na farko, kuma yankan hannu na al'ada zai haifar da bursu ko rashin daidaituwa a cikin samfuran yanke. A wannan zamanin na neman babban inganci, aikin hannu yana da ƙarancin ƙarancin yanayi, kuma zai haifar da ɓarna na kayan. Sabili da haka, kayan aikin CNC don yankan bangarori masu ɗaukar sauti ta atomatik yana da mahimmanci.

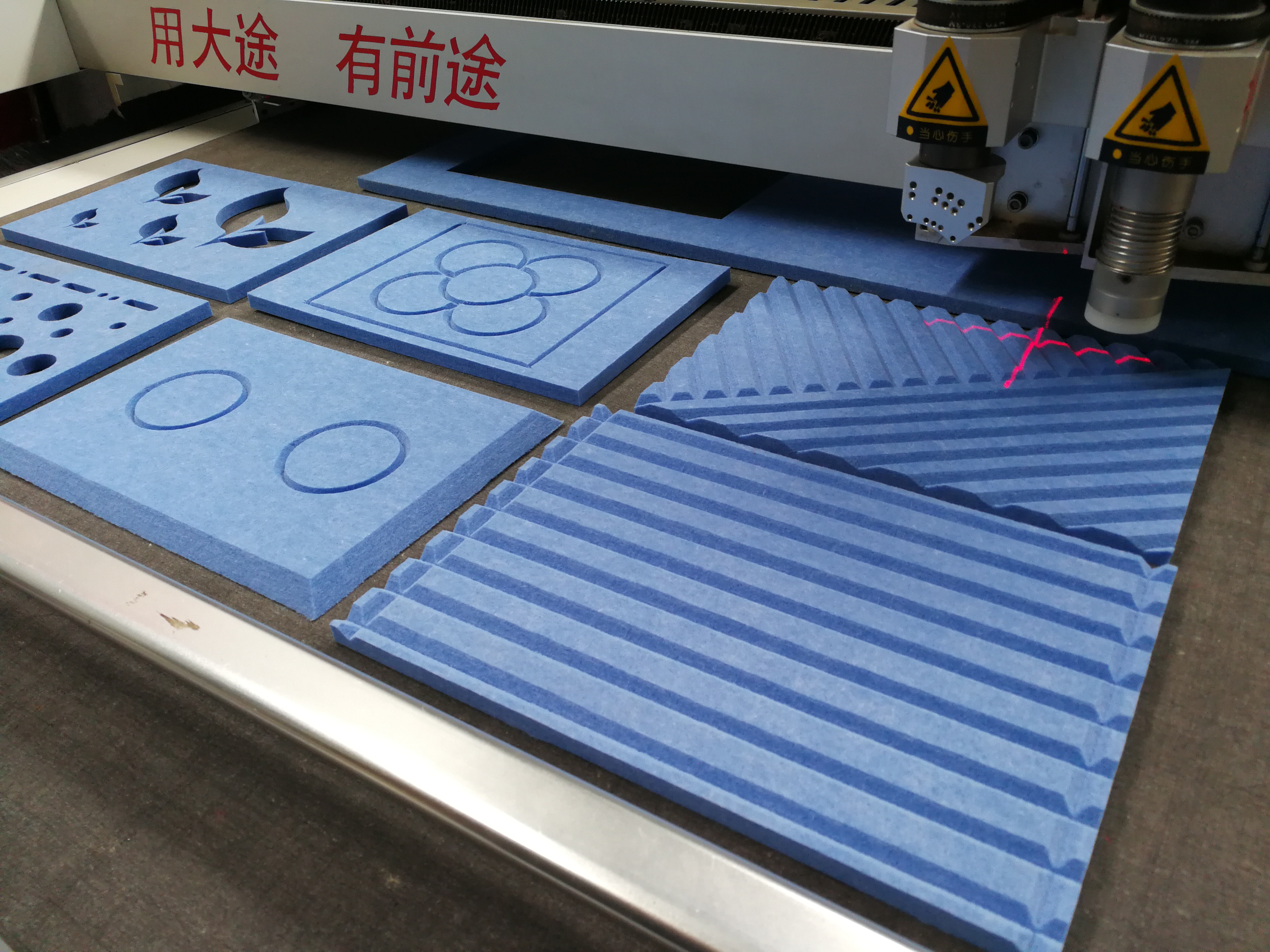

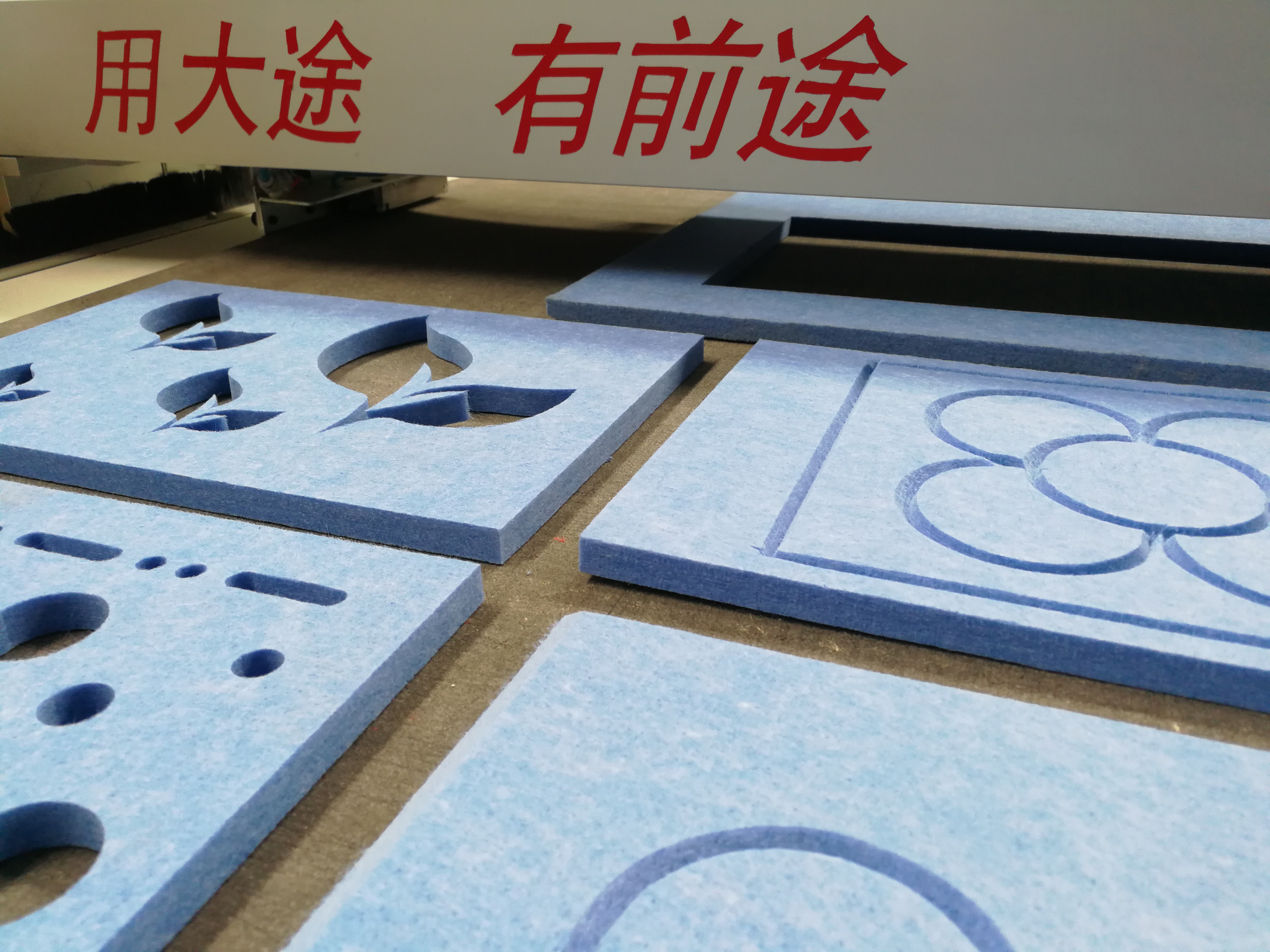

A cikin yankan bangarori masu ɗaukar sauti,Shandong Datu na'ura mai ɗaukar sautihar yanzu rungumi dabi'ar girgiza wuka yankan, da kuma janar abun yanka shugaban mariƙin za a iya sanye take dawuka mai girgiza, beveling wuka, V-CUT Knife, milling wuka, ja wuka da creasing wuka, rabin wuka da sauran daban-daban wukake iya sauri kammala daban-daban matakai kamar cikakken-yanke, rabin-yanke, naushi, slotting, chamfering, creasing, da dai sauransu. Kuma yankan gefen yana da tsabta kuma ba tare da burr ba. Kayan aikin yana ɗaukar software na CAM da kansa ya haɓaka tashandong Datu, wanda ya tsara tsarin inganta yanayin overcutting na kayan aiki, yana mayar da zane mai zane zuwa babban mataki, kuma yana kawo wa abokan ciniki sakamako mai gamsarwa. Ana gano lallausan tebur ta hanyar gano nesa mai tsayi, kuma ana gyara jirgin a ainihin lokacin ta hanyar software don tabbatar da sakamako mai inganci.

Lokacin aikawa: Agusta-29-2022